As a partner of DYNEX pump in China, since entering China for eight years, DYNEX pump has won a lot of reputation for its unique characteristics "high pressure, large flow". As a DYNEX pump and valve, which has been tested for sixty years, it has not only won the reputation of the testing industry, but also involves the power and steel industry.

Air and other areas of high precision.

How does the pump work

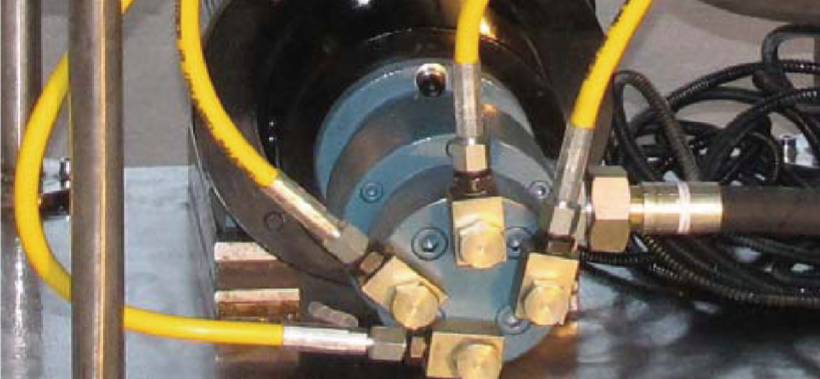

When the pump runs, the one-way valve of each plunger opens and closes in turn, thus directing the fluid out of the oil port.

The slalom disc pushes the plunger as a reciprocating motion. In extension travel, each plunger is filled with oil through an oil absorption valve.

In the compression stroke, the oil suction valve closes, the oil pressure of the plunger cavity continues to rise half over the load pressure, the pressure valve is pushed open and the oil of the seal cavity is pumped out. The output of each plunger flows together at the end of the pump, and output through the oil outlet.

The selection of one way valve valve pump has ten advantages:

1 wide fluid compatibility

The pump can operate reliably for all kinds of fluid with low lubricity and low viscosity. The design of rotary slanting disc and one-way valve valve plunger reduces the internal negative wear, making the starting torque lower and the life longer.

2 bi-directional rotation

No matter what the motor or engine is rotating, only one type of pump is needed. No matter how the drive axis turns, this kind of quantitative pump can provide the same output flow.

3 high power output

The compact design allows the pump to have a greater ratio of power to weight. The slanted disc is connected to the drive shaft by the key, and the plunger body is still not moving, so the pump can bear a greater load than the ordinary designed pump.

4 flexible installation

The direction of the pump is not restricted, which ensures the flexibility of the installation of the system. The use of the casing drain allows the pump to be installed vertically and ensures good internal lubrication during long operation.

5 simplified multifunction circuit

A multi - outlet pump can replace the loop system of multiple pumps. The pump can provide more accurate flow distribution than the shunting valve for synchronous motion.

6 anti cavitation damage

An accidental entry into the cavitation or suction hole of the system will lead to rapid damage to the general type of pump. And the one-way valve valve pump will reduce the negative pressure vibration, because only after the pump chamber fluid reached the load pressure, the pressure inlet one-way ball valve will leave the seat.

7 energy saving

The straight - seat one-way ball valve reduces the internal leakage and provides a higher volume efficiency than the ordinary pump. Unlike the flow plate pump, the design does not require the unloading groove.

8 pressure can reach 138MPa

The pump can be operated at high pressure and extreme temperature. Straight - seat unidirectional ball valves also have better wear resistance and higher volumetric efficiency, especially for lubricated fluids.

9 anti pollution

The pump can work in a dirty environment because it has a higher pollution resistance than a common pump. Large bore input and output channels allow pollutants to be washed through the pump chamber.

10 do not need to run oil

Using a single fluid design, internal lubrication is maintained on a working fluid, and the cost of additional internal lubrication or special maintenance is reduced. The cross contamination between different fluid media is also avoided.

This is a high reliability of the hydraulic pump for extreme conditions

The unidirectional valve valve design provides high reliability, long life, and will not reduce efficiency even when it is used over life. When other pumps have been damaged, the pump can continue to work, even at high pressure, contaminated fluid, and long and high strength. When absolutely reliable work is needed, it should be absolutely necessary

Tolerance of pollution

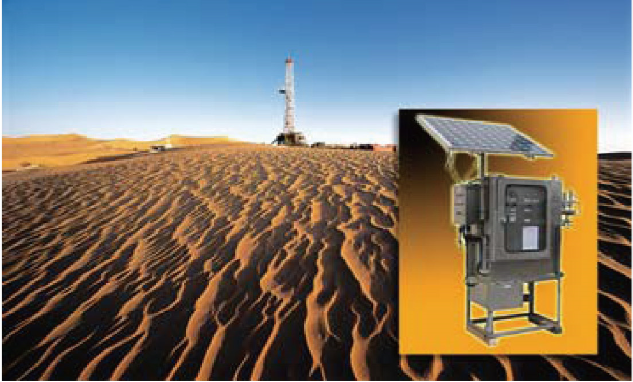

The DYNEX pump can still ensure long life operation in extreme environment. The pump can withstand dirty medium and high temperature without damage. It is an ideal choice for the dust dirt that can not be completely filtered out. Its applications include steel metallurgy, metal processing, rock crushing equipment, and solar power equipment operating in remote areas around the world.

Bi-directional rotation

Bi-directional rotation

The output flow of the DYNEX quantitative pump is not affected by the direction of rotation.

This avoids the improper installation of the pump or the electrical wiring

The damage to the hydraulic system caused by incorrect results.

Regardless of the rotation of the motor or engine,

All only need to choose a type of pump.

Anti cavitation damage

When air accidentally enters the system, other designed pumps will be damaged. If the liquid level falls below the oil suction port or the oil inlet valve is closed, the other pumps will soon be damaged. The DYNEX pump is resistant to cavitation damage because the oil pressure one-way valve will not leave the seat until the oil reaches the load pressure.

Simplified multifunction circuit

The output of each plunger of the DYNEX pump is independent of each other. This allows a multi - outlet pump to replace up to ten pumps. The fluid at each outlet can work under different pressures and not interfere with each other. The multiple plunger output can also be combined to provide different displacement. The flow accuracy of the pump is higher than that of the shunt valve when the synchronous operation is needed.

![]()