Marlni pump driver low working temperature, long service life and convenient maintenance. In the process of designing a new modular drive, we started from the drawing board and developed the products leading to all the competitors step by step.

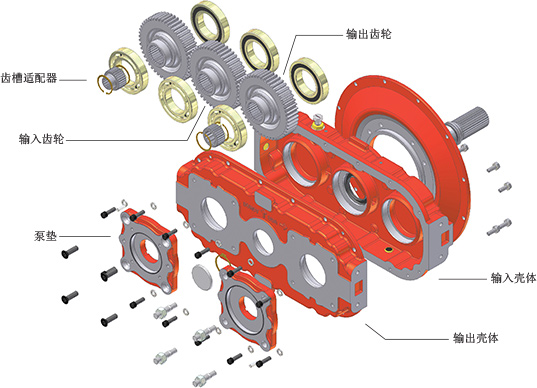

Continuously flowing through the bearings to ensure that the alveolus can be lubricated well when starting. All pumps are used Marlin drive 10 cylindrical gear, installed in a heavy duty ball bearing. In addition, the pump body is also equipped with cogging and cogging adapters, which can be compatible with any type of pump shaft and reduce operation noise.

Our engineering team reacted quickly and could modify the modular design in a short period of time according to different custom applications. With our first class customer service and a shorter delivery cycle, you will get an excellent solution to the pump drive.

Modular design

Functional characteristics

1. patented modular design

2. patent cogging lubricating mechanism, installed inside the cast iron shell

3. AGMA10 gear to reduce operation noise

4. the whole system is equipped with fluorine rubber seal and O ring

5. one type gear and shaft (Solid-On-Shaft) design

6. large ball bearing and SOS gear to simplify maintenance work

7. simply replace the driver of the driver

8. provide a pump pad and a slot adapter that meets the SAE and DIN standards

9. provide optional equipment (cantilever load adapter and oil circulation system)

Product details

1. pump pad

Marlin pump pad without bearing cover. The advantage of this design is that the pump cushion can be removed without interrupting the internal operation of the gearbox and the occlusion between the bearing and the gear.

2. drive disk

Marlin pump drive is adopted in four disc drive. The drive disc is equipped with four thin plates, with a slight increase in width, but a large increase in rated performance. Thin plates have greater elasticity. When installed together, multiple plates absorb more engines than a single disk. The driving disk is no longer fixed with the input shaft, but can automatically adjust when the engine flywheel is not aligned, not only improving the ride comfort of the operation, but also prolonging the service life of the gearbox.